It’s difficult getting the dairy barn floor right, isn’t it? Say you go with concrete flooring, which is by far the most popular choice. While durable and easy to clean, it’s also the most unforgiving surface for cows. Make it too abrasive and you’ll speed up hoof wear, raising the incidence of lameness. If your concrete flooring is too smooth, it can lead to injuries as a result of poor traction.

There’s no doubt that barn floors are critically important. Dairy cows spend up to 12 hours a day on their feet so it’s obvious that ensuring their comfort is essential. You’ll get your rewards in the form of lower risk of hoof disease and lameness, increased productivity, and higher profitability.

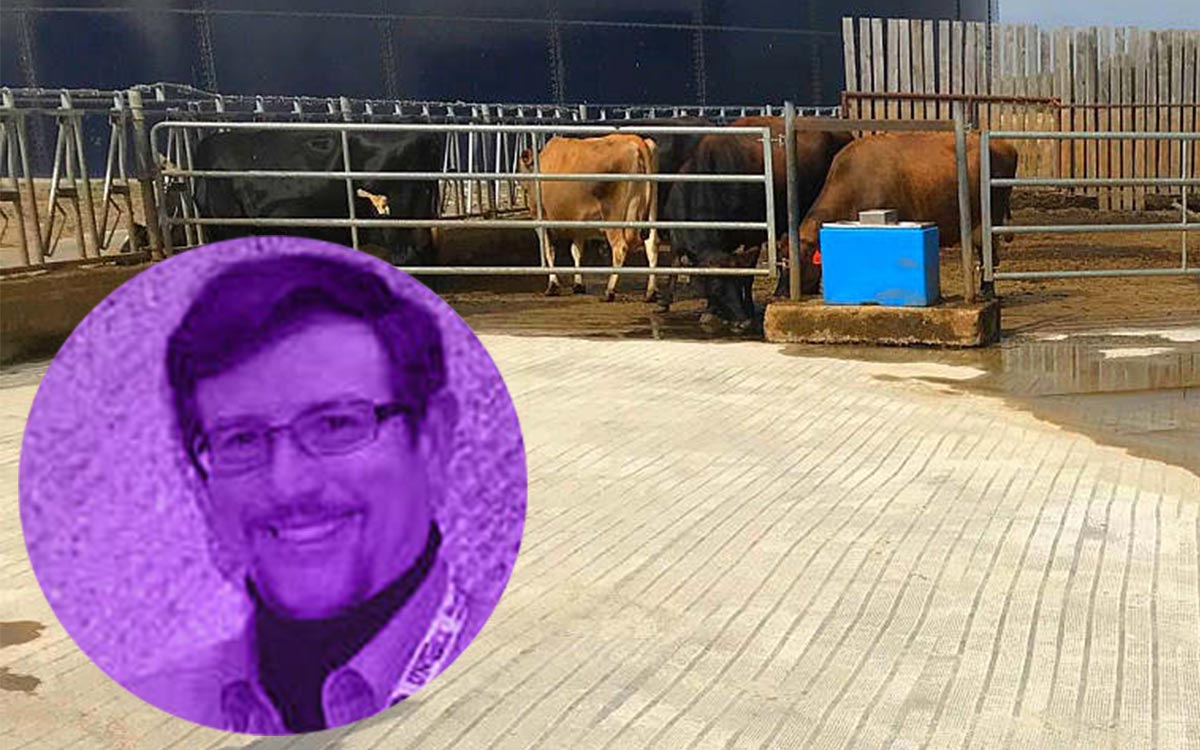

But even if we agree that cows must feel as comfortable as possible, it takes special attention to detail when it comes to concrete flooring. In search of an expert opinion on the matter, we got in touch with Tom Woodall. He is the owner of Woodstock, Ontario-based AGRI-TRAC™ – a company specializing in dairy barn renovations and stable installations. In 1993, AGRI-TRAC™ began working on the concept of Traction-Milling™. The patented equipment and process make concrete flooring non-slippery, thus helping prevent injuries and improving hoof health.

Our Koos Vis approached Tom with questions ranging from the start of it all to how hoof trimmers fit into the picture. So, sit back, reach for a refreshing drink, and enjoy the conversation.

Koos: You talk a lot about flooring in dairy facilities. Could you share with our readers how you got involved in the concrete flooring business? Let’s hear when and how it all started.

Tom: I grew up on a dairy farm with a 1940s-era barn: wooden stalls, a litter carrier manure system and old, very slippery, hand-mixed concrete flooring. Cows would always fall when we let them out. We didn’t know any different or how to fix it. In 1975, I had a summer job with a barn renovator installing stable cleaners and new tie-stalls. I fell in love with the difference we could make for farmers and their cows! I became his business partner and have been developing ways to improve barns and livestock handling facilities ever since.

As the dairy industry shifted to free-stall barns, so did we and flooring became more and more of an issue. Questions started cropping up such as what was best for excellent traction versus hoof wear, lameness, and ease of keeping a floor clean. Easy to do when pouring a new floor, but what to do about existing floors that became slippery? Breaking out 4-6 inches of perfectly good concrete because the top 1/8th of an inch was wrong simply did not make sense. So, we consulted with hoof trimmers and dairy producers for several years and combined their input with what we already knew from 25 years of pouring barn floors to develop a way of easily and economically changing that top smooth surface to provide the perfect texture for traction without hoof damage.

Since 1997, we have provided 6 million sq ft of Traction-Milling™ in 2,250 facilities throughout Canada and the United States.

Koos: You have visited many farms in Canada. Why do people usually contact you?

Tom: There are two reasons. First, the farm has a slippery floor problem, and second, the farmer wants our advice before pouring a new floor. With my experience pouring floors between 1975 and 2001 and my old partner doing the same since the 1950s, there is a lot of practical know-how we have that cannot be gained from a laboratory or from books. I can talk with farmers on a common-sense level and with contractors on a common-experience level. Having gained that experience, I like sharing it for free for the same reasons I mentioned before. It’s amazing to see the difference it can make to a barn and the cows in it! Information based on common sense should not have a price tag attached to it.

Koos: You have a special, unique method for preventing cows from slipping on concrete flooring. Would you mind sharing how you work?

Tom: Not at all. This actually goes back to your first question. Concrete is a funny thing. Farmers often have this attitude of “pour it and forget it.” Wrong! It is a tool that needs care and maintenance, just like a combine or a tractor. Even more so because you use every minute of every day, hopefully for decades. With our patented equipment, we can reverse the damage, wear or neglect of existing floors. We do it by grinding the slippery surface off and creating a new texture right into the aggregate (stones), which is the hardest part of the concrete mix of sand, stones and Portland cement powder. Hence, a longer lasting texture than what you can get with pouring, brooming, or imprinting. We also provide maintenance tips to give that floor and texture as long a life span as possible.

Koos: Is it important for you to know the condition of the hooves and to have contact with the farm’s hoof trimmer?

Tom: Cows are no different from humans when it comes to feet. If your feet hurt, your whole body hurts. If we have even a slight pain in our foot, we do the “head-bob” the same as a lame cow does. With livestock, there are so many reasons and variables that contribute to lameness. Who better than your hoof trimmer to know what those variables are from one farm to the next? On a farm where hoof health is good, there should be no problems with the Traction-Milling™ of the floor. Where hoof condition is a problem, it’s best to consult the hoof trimmer.

Depending on the problems, the particular floor areas or amount to be done can be determined to ensure the hooves heal at the fastest rate. In some cases, Traction-Milling™ will help the healing process. Constant slipping or sliding will cause hoof problems. Think about when you use a shovel: the hand that is constantly sliding gets the blister, not the hand that has a firm hold. It’s the same with a hoof. When it slips on a smooth or grooved floor, it often wears on the sides or the heel. If there is good traction, there is no frictional wear. The only time there will be wear is when the cow is turning. That wear will be on the toes, not on the heels. You want that and so does the hoof trimmer.

Thank you, Tom! If you need additional information, you can contact Tom at:

Tom Woodall

AGRI-TRAC Inc.

986 Lansdowne Ave.

Woodstock, Ontario N4S 7V9

Canada

Toll-free: 1-877-966-3546

Cell: 519-536-6985